RM-RGM-ITG Servo Rotary Gripper

Highly Integrated

Large Torquee

Grip and Rotate without mutual affect

Highly Integrated

Large Torquee

Grip and Rotate without mutual affect

| Item | Parameters | |||

|---|---|---|---|---|

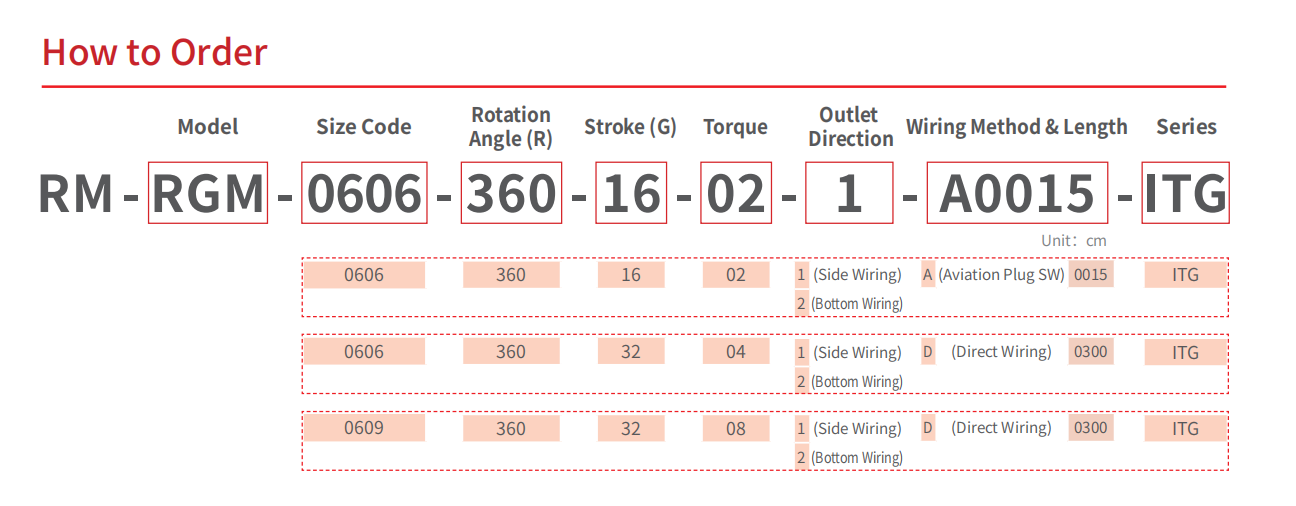

| Model | Model | RM-RGM-0606-360-16-02-ITG | RM-RGM-0606-360-32-04-ITG | RM-RGM-0609-360-32-08-ITG |

| Weight (kg) | 0.42 | 0.7 | 1.1 | |

| Dimensions (mm) | 45*30*155 | 55.9*43.9*165.5 | 74*45*161.5 | |

| Stroke (mm) | 0~16 | 0~32 | 0~32 | |

| Performance | Gripping Force1 (N) | 4~24 | 30~100 | 30~100 |

| Max.opening/closing Time (s) | 0.15/0.15 | 0.3/0.3 | 0.3/0.3 | |

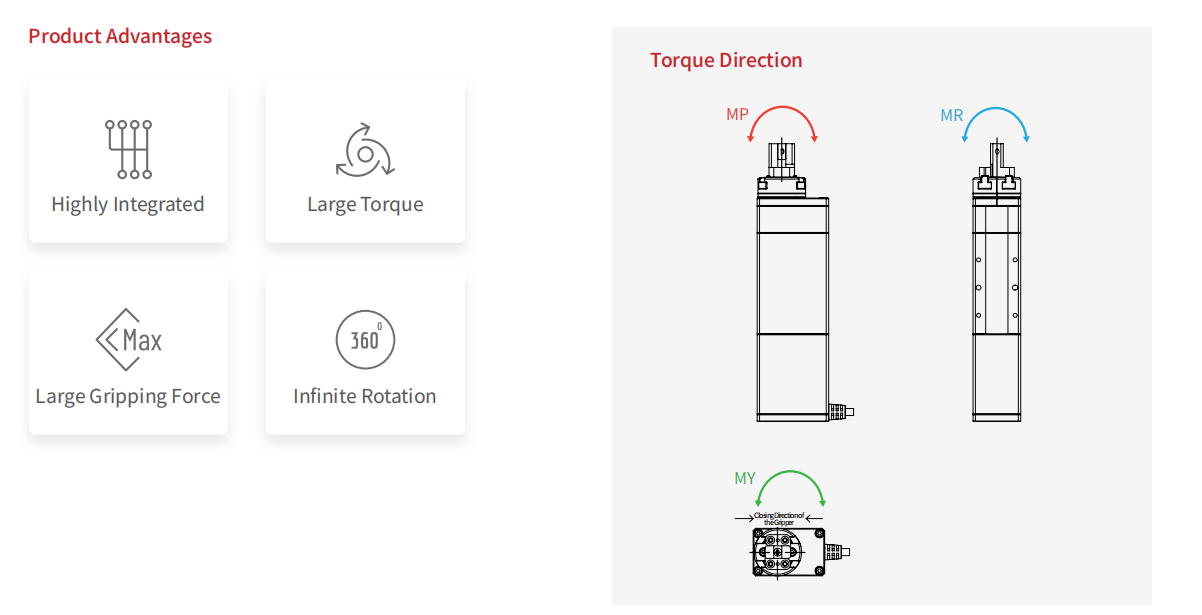

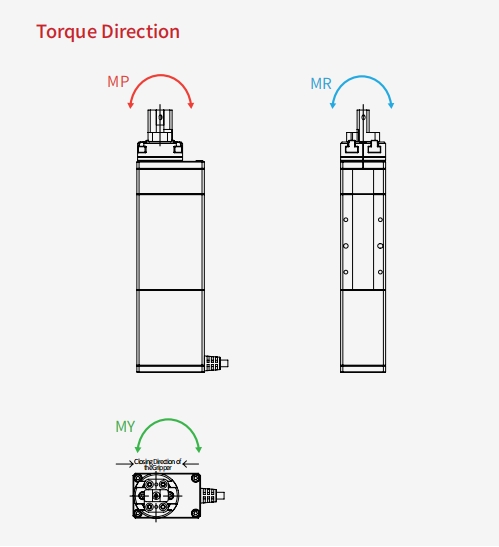

| Allowable Static Load Moment (N.m) | MR: 1.5, MP: 1.5, MY: 1.5 | MR: 2.1, MP: 2.1, MY: 2.1 | MR: 2.1, MP: 2.1, MY: 2.1 | |

| Rated Torque (N.m) | 0.2 | 0.4 | 0.8 | |

| Peak Torque (N.m) | 0.35 | 1.2 | 1.5 | |

| Max.allowable Inertia (kg/mm²) | 100 | 200 | 200 | |

| Repeat Positioning Accuracy2 (mm) | ±0.02 | ±0.02 | ±0.02 | |

| Rotation Repeatability (°) | ±0.05 | ±0.05 | ±0.05 | |

| Min/Max Rotation Angle | No Limitation | No Limitation | No Limitation | |

| Max.speed(°/s) | 1000 | 1100 | 2160 | |

| Control | Controller | Controller Built-in | Controller Built-in | Controller Built-in |

| Supporting Bus Protocols | Modbus RTU | Modbus RTU | Modbus RTU | |

| Operating Environment | Rated Voltage (V) | DC24±10% | DC24±10% | DC24±10% |

| Rated Current (A) | 1.8 | 1.8 | 2 | |

| Peak Current (A) | 4 | 4 | 4 | |

| Usage Environment | 0~40°C, <85%RH (Without condensation) |

0~40°C, <85%RH (Without condensation) |

0~40°C, <85%RH (Without condensation) |

|

| Protection Class IP | IP40 | IP40 | IP40 | |

1. The drawings provided in this Catalogue are for the default standard model. If you require other models with different motor directions, outlet directions, or outlet methods, please contact your local sales representative to obtain the drawing.

2. If you require a product with a brake, please contact your sales representative for a drawing.

RM-RGM-ITG is an advanced electric rotary gripper designed for applications requiring both gripping and rotational motion. Built with dual servo systems and integrated control modules, it delivers precise gripping force and smooth, programmable rotation within a single compact unit.

Powered entirely by servo technology, the RM-RGM-ITG Servo Rotary Gripper offers high accuracy in force control, rotation speed, and positioning. It can directly replace pneumatic rotary grippers, providing a cleaner, more energy-efficient, and maintenance-friendly solution for modern automation environments.

RM-RGM-ITG Rotary Gripper is built with dual servo systems and integrated control modules in a single compact unit, significantly reducing the installation footprint.

Communication protocol of RM-RGM-ITG Rotary Gripper: Modbus RTU

The rotary unit and gripper unit cannot be disassembled. For maintenance, please refer to the RM-RGM-ITG user manual.

The fingers/fixtures shown in the images are for demonstration purposes only and are not included with the gripper. Users need to design the fingers/fixtures according to their specific application or workpiece.

No. The ITG model has a built-in controller integrated into the unit.

RM-RGM-ITG Rotary Gripper features:

Medical Manufacturing

In Vitro Diagnostics / Laboratory Automation

Cosmetics Production Lines

3C Electronics / Automotive Manufacturing / Semiconductors / Industrial Automation