GBM-ITG-Micro Gripper (ITG)

Slim-body Design

Compact Size with Large Stroke

Adaptive Gripping

Slim-body Design

Compact Size with Large Stroke

Adaptive Gripping

| Item | Parameters | ||

|---|---|---|---|

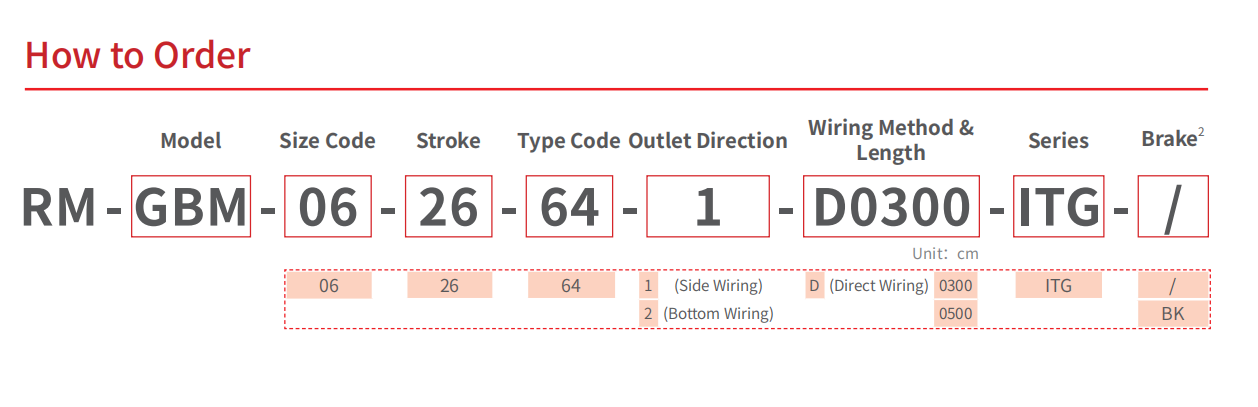

| Model | Model | RM-GBM-06-26-64-ITG | |

| Size Code | 06 | ||

| Weight (kg) | 0.4 | ||

| Dimensions (mm) | 95*55*29 | ||

| Performance | Stroke (mm) | 26 | |

| Max.gripping Force¹ (N) | 50 | ||

| Repeat Positioning Accuracy (mm) | ±0.02 | ||

| Max.opening/closing Time (s) | 0.45/0.45 | ||

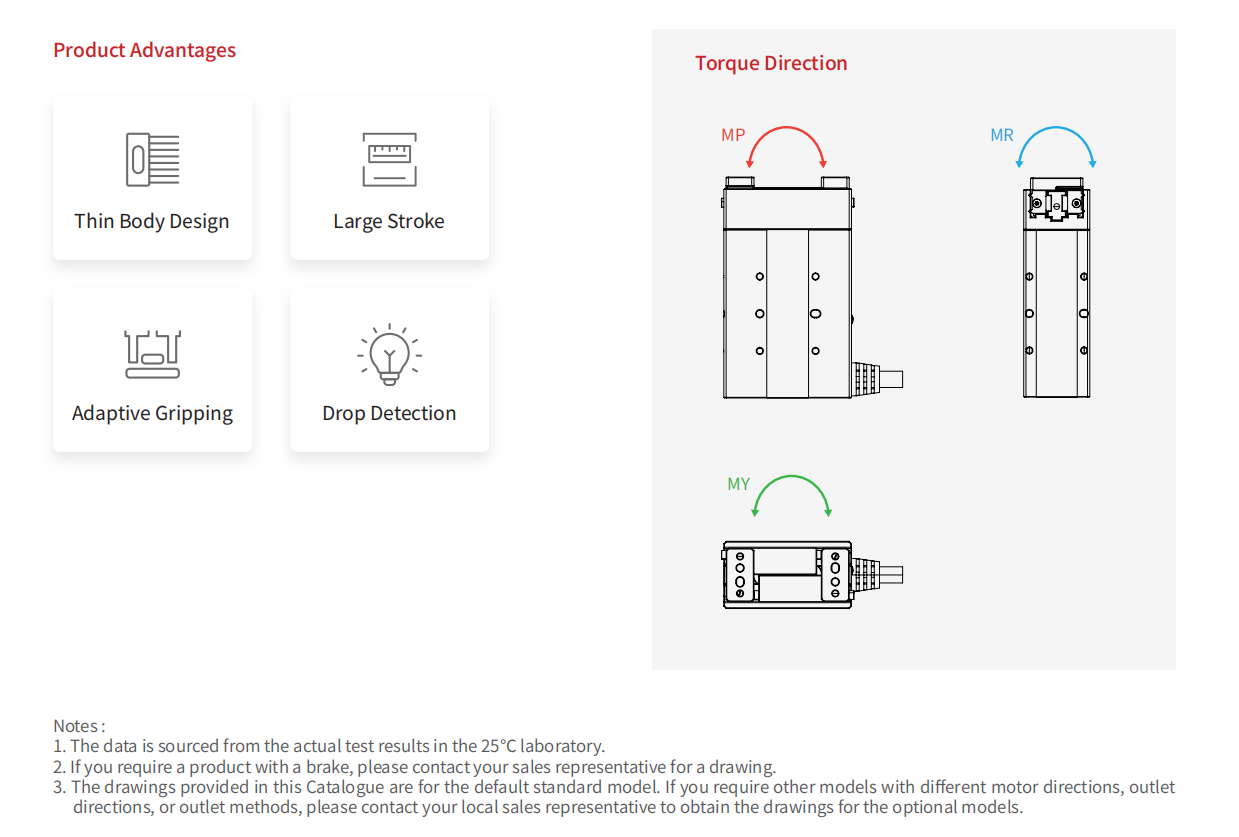

| Permissible Load Torque (N.m) | MR: 2.5, MP: 2, MY:3 | ||

| Control Method | Controller | Controller Built-in | |

| Control Method | Bus | Modbus RTU | |

| Interface | I/O | ||

| I/O Interface | Input 3 Points(NPN), Output 3 Points(NPN) | ||

| Operating Environment | Rated Voltage (V) | 24±10% | |

| Rated Current (A) | 1 | ||

| Usage Environment | 0~40°C, < 85%RH (Without condensation) | ||

| Protection Class IP | IP40 | ||

No. "ITG" stands for "Integrated," meaning the controller is built into the product body. No additional controller is required.

All RobustMotion (RM) electric actuators, including the RM-GBM-ITG series, use servo motors.

I/O and Modbus RTU.

DC 24±10%

RM-GBM-ITG does not have a self-lock mechanism.

Yes. Except for the RM-EGB series, all products require RM software-V6 Version to set motion commands.

The RM-GBM-ITG Micro Gripper is widely used in industrial automation for precision manufacturing, such as 3C electronics and semiconductor factories. Typical applications include precision pick-and-place of delicate components, such as small electronic parts, optical fibers, sensor elements, battery cells, and other miniature components.

Yes. The RM-GBM-ITG supports drop detection. It also offers adjustable gripping force, along with the capability to identify different workpiece dimensions and output length measurements.

Detailed maintenance instructions are provided in the user manual for each product.

No. For applications requiring high force control accuracy, please refer to the SoftForce® High-precision Force Controlled Electric Gripper series. For more details, please contact RobustMotion or an official RobustMotion distributor in your region.