WRPLA——Wide Platform-type Linear Actuator

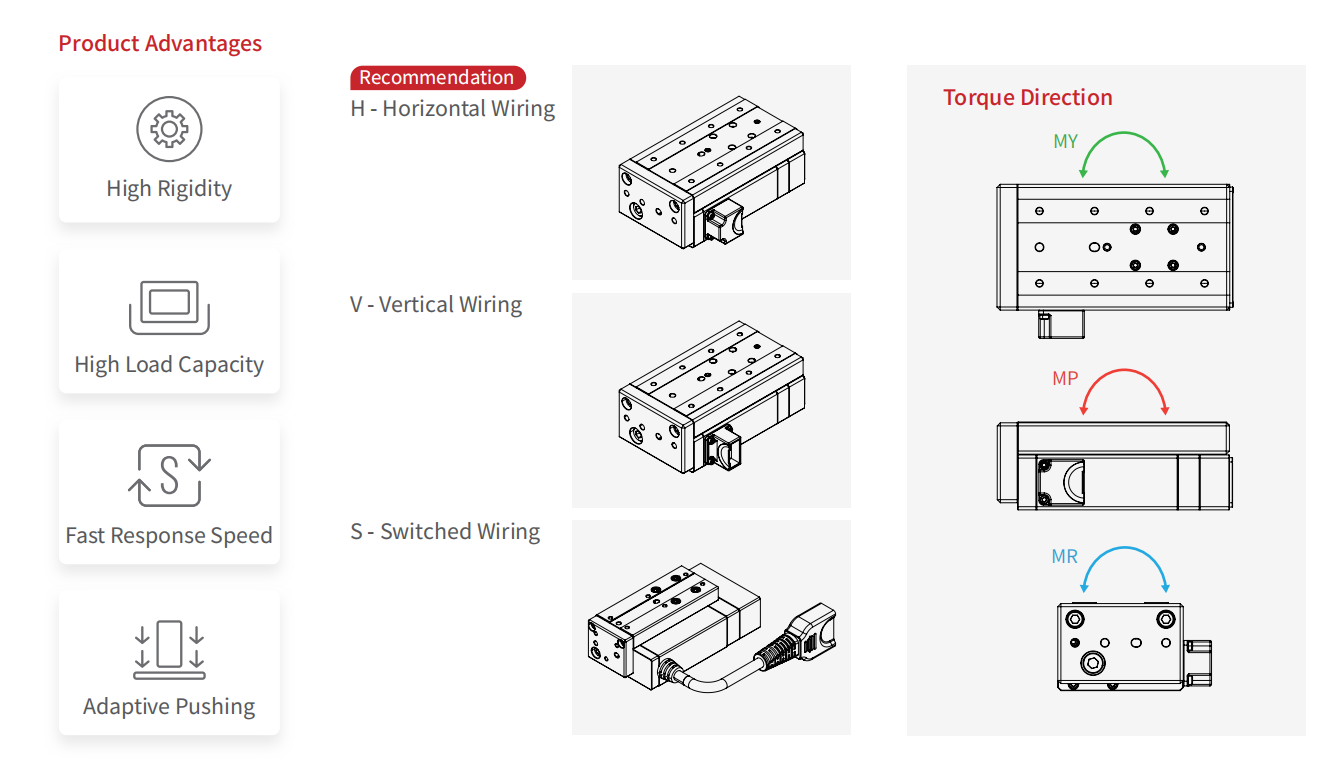

High Rigidity

High Load Capacity

Fast Response Speed

Adaptive Pushing

High Rigidity

High Load Capacity

Fast Response Speed

Adaptive Pushing

| Item | Parameters | ||

|---|---|---|---|

| Model Description | Model | RM-WRPLA-11-50-2-ITG | |

| Size Code | 11 | ||

| Weight (kg) | 1.6 | ||

| Dimensions (mm) | 150*80*56 | ||

| Performance | Stroke (mm) | 50 | |

| Lead (mm) | 2 | ||

| Max.speed (mm/s) | 100 | ||

| Max. pushing Force1 (N) | 300 | ||

| Max. load Mass (kg) | Horizontal | 6 | |

| Vertical | 0.5 | ||

| Repeat Positioning Accuracy (mm) | ±0.02 | ||

| Permissible Load Torque (N.m) | MR: 9.11, MP: 13.67, MY: 13.67 | ||

| Control | Control Method | Bus | Modbus RTU/CANopen |

| Interface | I/O | ||

| I/O Interface | Input 3 Points(NPN), Output 3 Points(NPN) | ||

| Operating Environment | Rated Voltage (V) | DC24±10% | |

| Rated Current (A) | 2 | ||

| Usage Environment | 0~40°C, < 85%RH (Without condensation) | ||

| Protection Class IP | IP40 | ||

| Item | Parameters | ||

|---|---|---|---|

| Model Description | Model | RM-WRPLA-11-50-2 | |

| Size Code | 11 | ||

| Types of Screws | Ball Screw | ||

| Weight (kg) | 1.6 | ||

| Dimensions (mm) | 150*80*56 | ||

| Performance | Stroke (mm) | 50 | |

| Lead (mm) | 2 | ||

| Max.speed (mm/s) | 100 | ||

| Max. pushing Force1 (N) | 300 | ||

| Max. load Mass (kg) | Horizontal | 6 | |

| Vertical | 0.5 | ||

| Repeat Positioning Accuracy (mm) | ±0.02 | ||

| Permissible Load Torque (N.m) | MR: 9.11, MP: 13.67, MY: 13.67 | ||

| Control Methods | Compatible Controllers | RM-C-20, RM-CEP-20, RM-CEM | |

| Supporting Bus Protocols | Modbus RTU, EtherCAT, Modbus TCP, PROFINET, EtherNet/IP, CC-LINK, CANopen | ||

| Supporting Control Methods | I/O, Pulse Control (Excluding RM-CEM Controller) | ||

| Operating Environment | Rated Voltage (V) | DC24±10% | |

| Rated Current (A) | 2 | ||

| Usage Environment | 0~40°C, < 85%RH (Without condensation) | ||

| Protection Class IP | IP40 | ||

ITG model (Integrated): built-in controller within the actuator body.

Split Type Model: actuator with an external controller; a compatible controller must be selected when ordering.

For the specific compatible controller, please refer to the technical specifications of the series. Confirmation of the required communication protocol will determine the exact controller model.

Yes. Except for the RM-EGB series, all RM electric actuators should be connected using RM Software (V6 version).

Please refer to the user manual for detailed maintenance instructions for each product.

An electric linear actuator converts electrical energy into precise linear motion, enabling pushing, pulling, lifting, or lowering of loads. Powered by electric motors and controlled by programmable electronics, these actuators provide accurate force and position control for a variety of factory automation and industrial applications, including:

Compared to pneumatic or hydraulic systems, electric actuators offer higher efficiency, cleaner operation, and superior motion accuracy. They provide high precision, repeatability, and programmable control, allowing real-time adjustment of speed, position, and force. With energy-saving operation, lower maintenance, and easy integration with digital control systems, electric actuators are widely used in industrial automation, robotics, intelligent manufacturing, and precision handling applications.