NPLA——Micro Platform Type Linear Actuator

Miniature Size

High Repeat Accuracy

High-speed & Stable

High Rigidity

Miniature Size

High Repeat Accuracy

High-speed & Stable

High Rigidity

| Item | Parameters | |||||

|---|---|---|---|---|---|---|

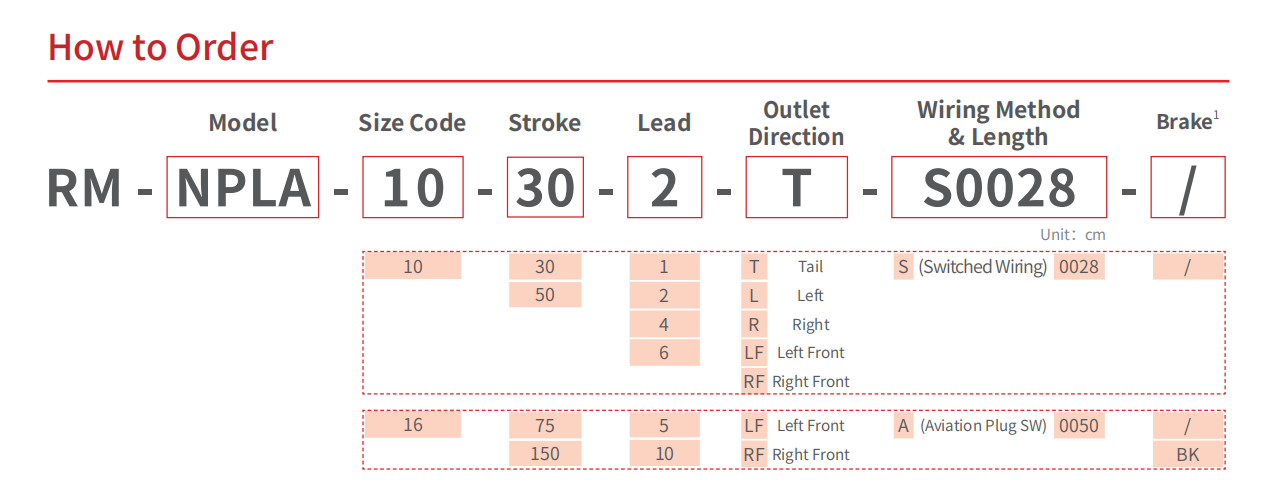

| Model Description | Model | RM-NPLA-10-30-1 | RM-NPLA-10-30-2 | RM-NPLA-10-30-4 | RM-NPLA-10-30-6 | |

| Size Code | 10 | 10 | 10 | 10 | ||

| Weight (kg) | 0.5 | 0.5 | 0.5 | 0.5 | ||

| Dimensions (mm) | 111.5*34*48 | 111.5*34*48 | 111.5*34*48 | 111.5*34*48 | ||

| Performance | Stroke (mm) | 30 | 30 | 30 | 30 | |

| Lead (mm) | 1 | 2 | 4 | 6 | ||

| Max.speed (mm/s) | 50 | 100 | 200 | 300 | ||

| Max. pushing Force (N) | 210 | 110 | 50 | 30 | ||

| Max. load Mass (kg) | Horizontal | 6 | 3 | 2 | 1.5 | |

| Vertical | 3 | 2 | 1 | 0.5 | ||

| Repeat Positioning Accuracy (mm) | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ||

| Permissible Load Torque (N.m) | MP: 9.75, MR: 11.31, MY: 3.75 | MP: 9.75, MR: 11.31, MY: 3.75 | MP: 9.75, MR: 11.31, MY: 3.75 | MP: 9.75, MR: 11.31, MY: 3.75 | ||

| Control | Compatible Controllers | RM-CEU, RM-CEM | RM-CEU, RM-CEM | RM-CEU, RM-CEM | RM-CEU, RM-CEM | |

| Supporting Bus Protocols | Modbus RTU, EtherCAT, Modbus TCP, PROFINET, EtherNet/IP, CC-LINK, CANopen | |||||

| Supporting Control Methods | I/O, Pulse Control (Excluding RM-CEM Controller) | |||||

| Operating Environment | Rated Voltage (V) | DC24±10% | DC24±10% | DC24±10% | DC24±10% | |

| Rated Current (A) | 1.25 | 1.25 | 1.25 | 1.25 | ||

| Cable Length (m) | 3/5 | 3/5 | 3/5 | 3/5 | ||

| Usage Environment | 0~40°C, < 85%RH (Non-condensing) | |||||

| Protection Class IP | IP40 | IP40 | IP40 | IP40 | ||

| Item | Parameters | |||||

|---|---|---|---|---|---|---|

| Model Description | Model | RM-NPLA-10-50-1 | RM-NPLA-10-50-2 | RM-NPLA-10-50-4 | RM-NPLA-10-50-6 | |

| Size Code | 10 | 10 | 10 | 10 | ||

| Weight (kg) | 0.6 | 0.6 | 0.6 | 0.6 | ||

| Dimensions (mm) | 131.5*34*48 | 131.5*34*48 | 131.5*34*48 | 131.5*34*48 | ||

| Performance | Stroke (mm) | 50 | 50 | 50 | 50 | |

| Lead (mm) | 1 | 2 | 4 | 6 | ||

| Max.speed (mm/s) | 50 | 100 | 200 | 300 | ||

| Max. pushing Force (N) | 210 | 110 | 50 | 30 | ||

| Max. load Mass (kg) | Horizontal | 6 | 3 | 2 | 1.5 | |

| Vertical | 3 | 2 | 1 | 0.5 | ||

| Repeat Positioning Accuracy (mm) | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ||

| Permissible Load Torque (N.m) | MP: 9.75, MR: 11.31, MY: 3.75 | MP: 9.75, MR: 11.31, MY: 3.75 | MP: 9.75, MR: 11.31, MY: 3.75 | MP: 9.75, MR: 11.31, MY: 3.75 | ||

| Control | Compatible Controllers | RM-CEU, RM-CEM | RM-CEU, RM-CEM | RM-CEU, RM-CEM | RM-CEU, RM-CEM | |

| Supporting Bus Protocols | Modbus RTU, EtherCAT, Modbus TCP, PROFINET, EtherNet/IP, CC-LINK, CANopen | |||||

| Supporting Control Methods | I/O, Pulse Control (Excluding RM-CEM Controller) | |||||

| Operating Environment | Rated Voltage (V) | DC24±10% | DC24±10% | DC24±10% | DC24±10% | |

| Rated Current (A) | 1.25 | 1.25 | 1.25 | 1.25 | ||

| Cable Length (m) | 3/5 | 3/5 | 3/5 | 3/5 | ||

| Usage Environment | 0~40°C, < 85%RH (Non-condensing) | |||||

| Protection Class IP | IP40 | IP40 | IP40 | IP40 | ||

| Item | Parameters | |||||

|---|---|---|---|---|---|---|

| Model Description | Model | RM-NPLA-16-75-5 | RM-NPLA-16-75-10 | RM-NPLA-16-150-5 | RM-NPLA-16-150-10 | |

| Size Code | 16 | 16 | 16 | 16 | ||

| Weight (kg) | 1.4 | 1.4 | 2 | 2 | ||

| Dimensions (mm) | 164*58*63.5 | 164*58*63.5 | 237*58*63.5 | 237*58*63.5 | ||

| Performance | Stroke (mm) | 75 | 75 | 150 | 150 | |

| Lead (mm) | 5 | 10 | 5 | 10 | ||

| Max.speed (mm/s) | 250 | 380 | 250 | 380 | ||

| Max. pushing Force (N) | 360 | 180 | 360 | 180 | ||

| Max. load Mass (kg) | Horizontal | 18 | 15 | 18 | 15 | |

| Vertical | 6 | 3 | 6 | 3 | ||

| Repeat Positioning Accuracy (mm) | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ||

| Power Failure Auto-Lock | Optional Brake | Optional Brake | Optional Brake | Optional Brake | ||

| Permissible Load Torque (N.m) | MP: 18.13, MR: 19.11, MY: 18.13 | MP: 18.13, MR: 19.11, MY: 18.13 | MP: 18.13, MR: 19.11, MY: 18.13 | MP: 18.13, MR: 19.11, MY: 18.13 | ||

| Control | Compatible Controllers | RM-CEU, RM-CEM | RM-CEU, RM-CEM | RM-CEU, RM-CEM | RM-CEU, RM-CEM | |

| Supporting Bus Protocols | Modbus RTU, EtherCAT, Modbus TCP, PROFINET, EtherNet/IP, CC-LINK, CANopen | |||||

| Supporting Control Methods | I/O, Pulse Control (Excluding RM-CEM Controller) | |||||

| Operating Environment | Rated Voltage (V) | DC24±10% | DC24±10% | DC24±10% | DC24±10% | |

| Rated Current (A) | 5 | 5 | 5 | 5 | ||

| Cable Length (m) | 3/5 | 3/5 | 3/5 | 3/5 | ||

| Usage Environment | 0~40°C, < 85%RH (Non-condensing) | |||||

| Protection Class IP | IP40 | IP40 | IP40 | IP40 | ||

RM-NPLA Micro Platform-type Linear Actuator features a compact design well-suited for factory automation. It offers multiple stroke and force options, enabling flexible configuration for different load and process requirements. With high positioning repeatability and stable high-speed performance, the RM-NPLA supports a wide range of applications across 3C electronics, precision manufacturing, and automotive assembly.

ITG model (Integrated): built-in controller within the actuator body.

Split Type Model: actuator with an external controller; a compatible controller must be selected when ordering.

For the specific compatible controller, please refer to the technical specifications of the series. Confirmation of the required communication protocol will determine the exact controller model.

No. RM-NPLA is not equipped with a mechanical self-locking mechanism. If your application requires a braking function, please contact RobustMotion or an authorized RobustMotion distributor in your region.

The standard communication protocols supplied for overseas markets include I/O control, Modbus RTU, Modbus TCP, and EtherCAT. For the latest information, please contact RobustMotion or an official RobustMotion distributor in your region.

Yes. Except for the RM-EGB series, all RM electric actuators should be connected using RM Software (V6 version).

RM-NPLA Micro Platform-type Linear Actuator is widely used in precision linear motion tasks across multiple industries, including:

Please refer to the Maintenance section in the RM-NPLA User Manual.

Compared to pneumatic or hydraulic systems, electric actuators offer higher efficiency, cleaner operation, and superior motion accuracy. They provide high precision, repeatability, and programmable control, allowing real-time adjustment of speed, position, and force. With energy-saving operation, lower maintenance, and easy integration with digital control systems, electric actuators are widely used in industrial automation, robotics, intelligent manufacturing, and precision handling applications.